What is Powder Coating? A Complete Guide for Beginners

Ever noticed how some metal items—like bike frames, car rims, or patio furniture—have a smooth, tough finish that never seems to chip or fade? That’s likely powder coating at work.

But what exactly is it, how does it work, and why should you consider it over traditional paint? Let’s break it down in simple terms—no industry jargon, just straight-up useful info.

What Is Powder Coating? (And Why It’s Better Than Paint)

Powder coating is a dry finishing process where a fine powder (made of pigment and resin) is sprayed onto metal surfaces. Instead of using liquid solvents like regular paint, it relies on electrostatic attraction, meaning the powder sticks to the metal like a magnet.

Once applied, the coated object is baked in an oven, melting the powder into a hard, protective shell. The result? A finish that’s:

- More durable than paint (no chipping or peeling).

- Eco-friendly (no toxic solvents or strong fumes).

- Versatile (comes in glossy, matte, metallic, and even textured finishes).

How Powder Coating Works: Step by Step

1. Prepping the Surface (The Secret to a Long-Lasting Finish)

Before any powder touches the metal, it must be squeaky clean. Even tiny bits of grease or rust can ruin adhesion. Common prep methods:

- Sandblasting – Blasts away grime and roughs up the surface for a better grip.

- Chemical Treatment – Uses acids or alkaline cleaners to remove oils and rust.

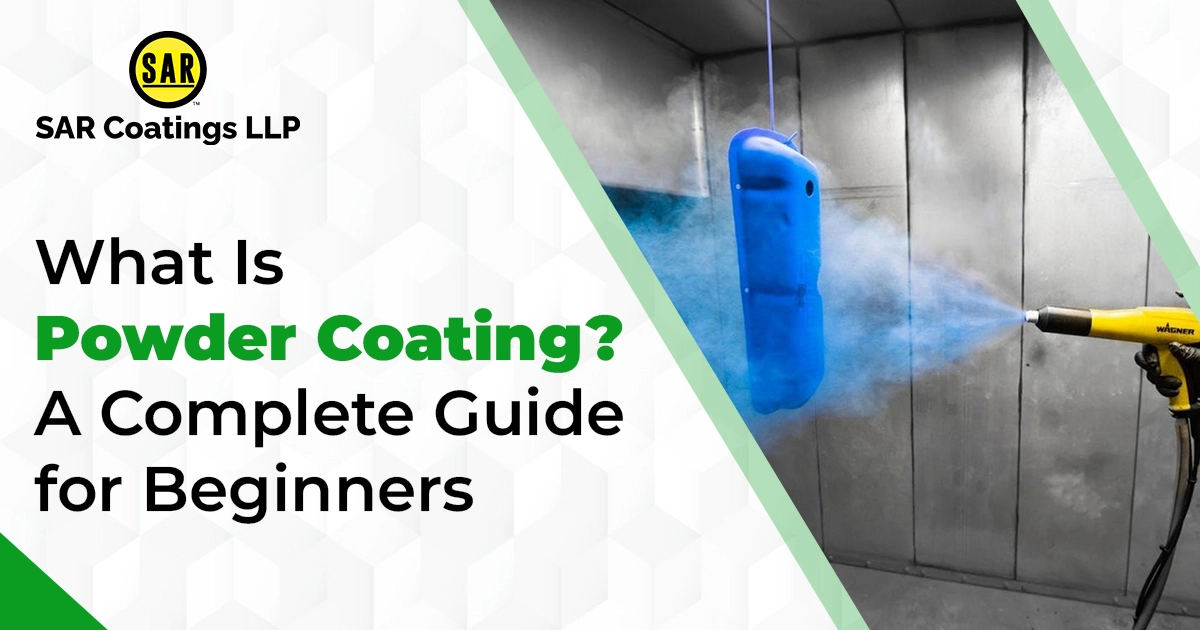

2. Applying the Powder (Where the Magic Happens)

A special electrostatic gun sprays the powder, giving it a positive charge. Since metal is grounded, the powder clings evenly, even on tricky shapes.

Bonus: Overspray can often be reused, making it way less wasteful than liquid paint.

3. Baking to Perfection (The Final Touch)

The coated piece goes into a curing oven (around 350°F–400°F). The heat melts the powder, turning it into a smooth, rock-hard layer that bonds to the metal.

Why Choose Powder Coating? (5 Big Advantages)

- Tough as Nails – Stands up to scratches, UV rays, and harsh weather.

- No Toxic Fumes – Unlike spray paint, it’s solvent-free and safer to apply.

- Smoother Finish – No brush marks or drips—just even, professional-looking coverage.

- Cost-Effective Long-Term – Lasts years longer than paint, saving recoating costs.

- Endless Customization – Metallic, neon, textured—you name it, there’s a powder for it.

Where Is Powder Coating Used? (You’ve Probably Seen It Everywhere)

- Cars & Motorcycles (wheels, engine parts, bumpers)

- Outdoor Gear (bike frames, grills, fencing)

- Home Appliances (washer drums, fridge panels)

- Industrial Equipment (tools, machinery, storage racks)

Powder Coating vs. Paint: Which Wins?

| Factor | Powder Coating | Traditional Paint |

| Durability | Resists chips, scratches, and fading | Peels over time |

| Eco-Friendliness | No VOCs, less waste | Contains solvents |

| Finish Quality | Smooth, even, thick coat | Can drip or streak |

| DIY-Friendly? | Needs special equipment | Easier for small projects |

Verdict: If you want a long-lasting, pro-grade finish, powder coating is the way to go. But for quick touch-ups, paint still has its place.

Can You Powder Coat at Home? (DIY Tips)

Yes, but with some caveats:

- You’ll need a powder coating gun and a dedicated oven (don’t use your kitchen one!).

- Small items (like tools or bike parts) are easiest.

- For big jobs (car frames, patio sets), pros do it better.

Final Thoughts: Is Powder Coating Worth It?

If you’re tired of repainting scratched-up metal or want a greener, tougher alternative, powder coating is a game-changer. It’s not just for factories—home gamers can try it too (with the right setup).