Achieving Corrosion Resistance with Zinc Plating (Rack)

In the world of manufacturing and metal finishing, corrosion resistance is a critical factor in ensuring the longevity and durability of various components. One effective method to combat corrosion and enhance the lifespan of metal parts is zinc plating. Protective coatings are created by this process that acts as a barrier between corrosive elements and metal substrates. Throughout this piece, we will examine the crucial elements and advantages of rack zinc plating when it comes to attaining corrosion resistance.

Understanding Zinc Plating (Rack)

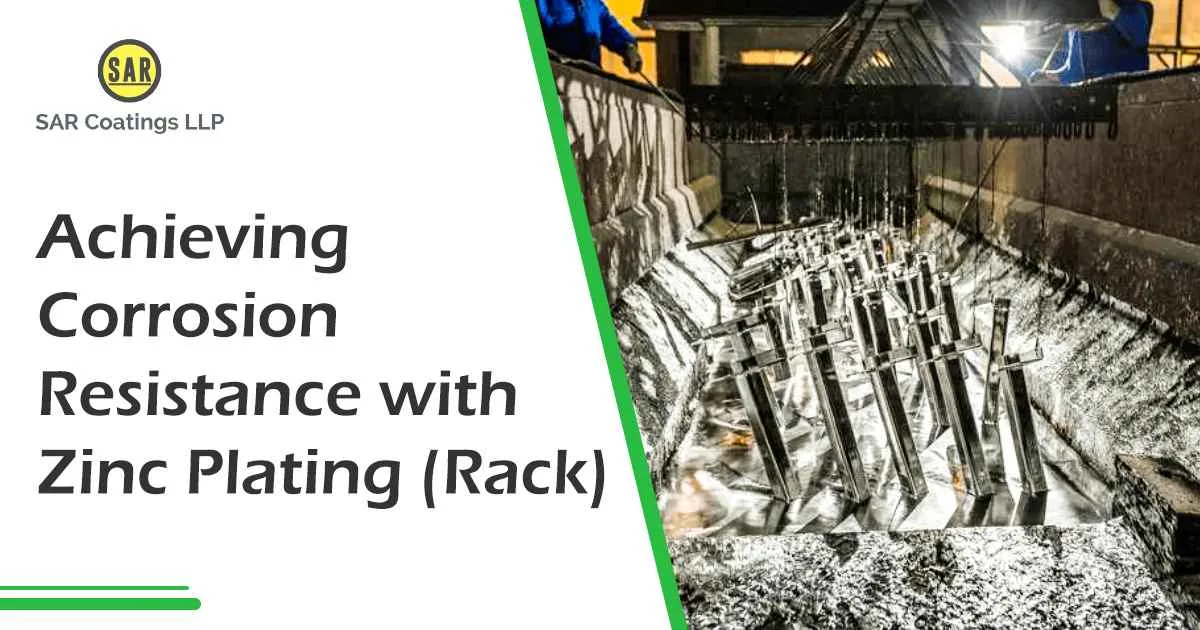

Zinc Plating (Rack) is a popular electroplating technique used to apply a layer of zinc to metal substrates. The process involves immersing the components in a specialised plating solution, which typically contains zinc ions and other chemicals necessary for the deposition process. Unlike barrel plating, where small parts are tumbled in a barrel, rack plating is ideal for larger and more delicate components that require individual attention and careful handling.

How Zinc Plating (Rack) Works

The plating process begins with thorough cleaning and preparation of the metal parts. The components are carefully mounted on racks, ensuring proper electrical contact for effective plating. Once secured, the racks are immersed in the plating bath, and an electric current is passed through the solution. This current triggers the deposition of zinc onto the metal surfaces, creating a uniform and adherent coating.

Benefits of Zinc Plating

- Corrosion Protection: The primary benefit of zinc plating (rack) is its exceptional corrosion resistance properties. The zinc coating acts as a sacrificial layer, providing a barrier against moisture, chemicals, and other corrosive substances that can lead to oxidation and degradation of the underlying metal. This protection is particularly crucial in industries such as automotive, aerospace, and marine, where components are exposed to harsh environments.

- Enhanced Aesthetics: In addition to its protective properties, the plating also offers aesthetic advantages. The plated components exhibit a bright, attractive appearance that can enhance the visual appeal of the finished product. This is especially beneficial for consumer goods, architectural hardware, and decorative items, where aesthetics play a significant role in customer perception.

- Uniform Coating Thickness: It ensures a uniform and controlled thickness of the zinc coating. This uniformity in zinc plating service is essential for maintaining consistent corrosion resistance across the entire surface of the part. By achieving a precise coating thickness, zinc plating ensures reliable protection and minimises the risk of localised corrosion or inadequate coverage.

- Versatility: This plating is a versatile process suitable for a wide range of metal substrates, including steel, iron, brass, and copper alloys. It can be applied to complex shapes and intricate parts thanks to the ability to position and secure components individually on the racks. As a result, the versatility makes rack plating a viable option for diverse industries and applications.

- Cost-Effective Solution: Moreover, it offers a cost-effective solution for achieving corrosion resistance compared to alternative methods such as stainless steel or specialised alloys. It allows manufacturers to protect metal components without compromising on material selection or incurring substantial expenses. This affordability makes it an attractive option for both small-scale production and large-volume manufacturing.

Your Ultimate Corrosion Defence

Zinc Plating (rack) is a highly effective method for achieving corrosion resistance in metal components. By applying a uniform layer of zinc, this process provides a protective barrier that prevents the degradation and deterioration of metal substrates. With its benefits of corrosion protection, enhanced aesthetics, uniform coating thickness, versatility, and cost-effectiveness, zinc plating is a valuable solution for industries seeking to prolong the lifespan and performance of their products.