ZINC PLATING BARREL

Our Zinc Barrel plant core expertise lies in providing exceptional Barrel type Zinc Electroplating services that are tailored to meet our customers exact requirements. We feel very dignified in delivering plating products of unmatched quality, boasting both aesthetic appeal and superior functionality that surpasses all test requirements with our latest cutting-edge technology and state-of-the-art machinery which is fully automatic and cater any small parts in the barrels providing a high-volume productivity on the electroplating services. The entire process line is efficiently managed and monitored through an advanced SCADA system, ensuring precision and control. Our Plating process sets itself apart by being Cyanide and utilizing an Alkaline solution that ensures an outstanding deposition of Zinc Metal.

We are using one of the globally renowned chemicals which also helps in building a sustainable future by having a compliance of ELV, REACH and ROHS globally. Resulting in excellent adhesion and coverage on any complex small shapes like recessed areas, edges and corners of metal.

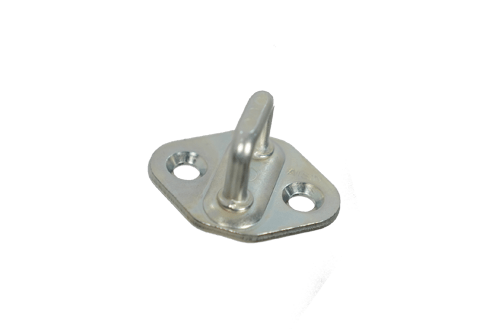

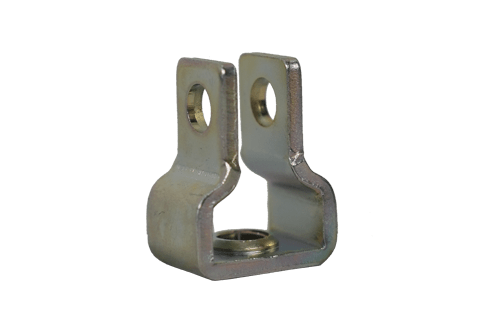

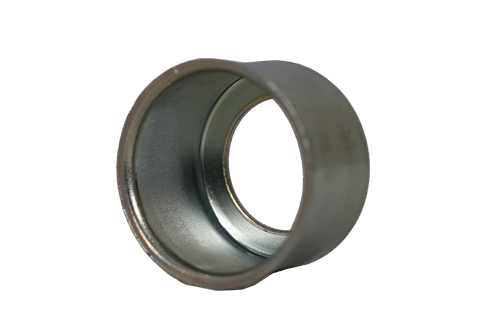

As we at SAR are doing this zinc plating with iridescent colour which can not only be used of metals to protect them from the corrosion process and increase the lifespan of the metal but also offer to give a decorative finish on the product by giving a bright and shiny finish which is visually very appealing making it relatively inexpensive compared to other metals used for electroplating.

To enhance efficiency and productivity, our plating services are equipped with some remarkable features which not only do zinc plating uniformly but increases the productivity. We are not just an electroplating service provider; we are passionate about the plating process. Our enthusiasm for what we do drives us to continually improve and innovate.

We take pride in offering top-notch zinc plating, passivation, and surface treatment services. Our unwavering commitment to delivering exceptional results, especially in the automotive sector, firmly establishes us as a trusted and reliable partner in the electroplating industry.

PRODUCT BENEFITS

- Ideal for bolts, screws, and other fasteners

- Up to 120 hours of White Rust in SST

- Aesthetically appealing RAINBOW color effect

FAQ's

Zinc plating barrel is a container used in electroplating processes to hold small parts and immerse them in a zinc plating bath. The barrel rotates or tumbles during plating to ensure even coating on all surfaces.

Electroplating is an electrochemical process used to deposit a thin layer of metal onto a conductive surface. It is commonly used to provide corrosion resistance, improve appearance, or enhance conductivity of the plated object.

Small to medium-sized metal parts with complex shapes, such as screws, bolts, nuts, washers, brackets, and other hardware components, can be plated using the barrel method.

In zinc plating, the parts to be plated are first cleaned to remove any dirt, oils, or oxides. They are then immersed in an electrolyte solution containing zinc ions. The solution is subjected to an electric current, which causes the zinc ions to deposit on the components’ surfaces.

Reputable plating service providers like Sarcoatings conduct various quality control tests to ensure the thickness, adhesion, and overall quality of the plated layer. They may provide certificates or reports upon request.